22

2023

-

12

LPS Multi-Pallet Flexible Processing Line

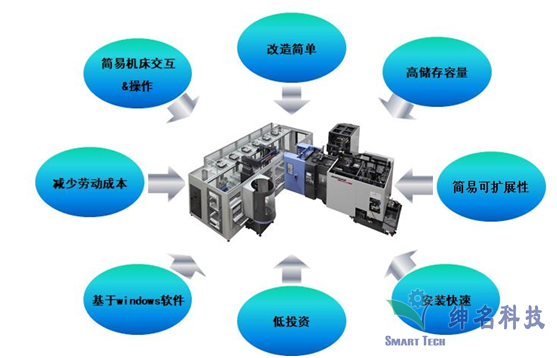

As customers' production models gradually shift from large-scale, integrated, and singular approaches to small-batch, diverse, and flexible methods, Beijing Smart Technology Co., Ltd. has customized the most optimized pallet automation system solutions for clients using Dean machine tools. This not only helps clients reduce labor costs but also improves the production line's operational efficiency and utilization rate.

LPS Multi-Pallet Flexible Processing Line

As customers' production models gradually shift from large-scale, integrated, and singular approaches to small-batch, multi-variety, and flexible directions, Beijing Smart Technology Co., Ltd. has customized the optimal pallet automation system solution for customers using Dean machine tools, helping customers reduce labor costs while improving the production line's operational rate and utilization.

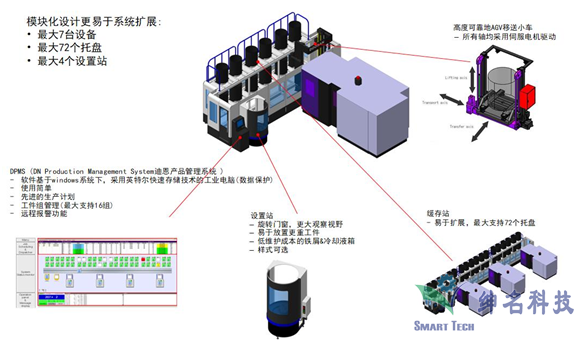

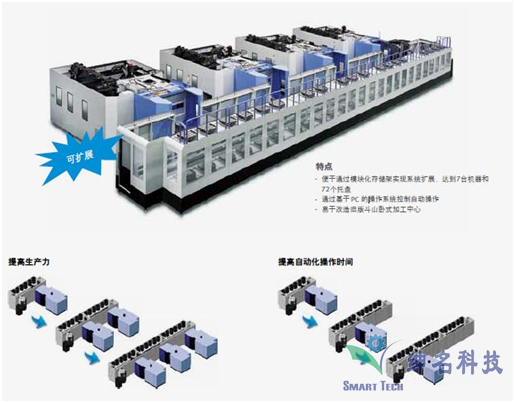

At the same time, considering the proportion of investment by end users in the early stages of the project, we have adopted the highly expandable and convenient Dean LPS multi-pallet system, which can support up to 72 pallets and 7 horizontal machining centers.

In addition, in response to the different types of products processed by end users, the LPS flexible production line can flexibly use heavy cutting hard rail horizontal machining centers, as well as high-speed, high-precision linear rail horizontal machining centers, to meet the differentiated processing needs of different customer groups.

NHM Hard Rail Series

High stability bed structure: The NHM series has undergone finite element method (FEM) analysis, analyzing the distribution of force support points on the overall integrated bed, ensuring uniform force during processing and improving processing stability.

The bed structure of this series, after analysis by mechanical software, is divided into an upper M-type and a lower W-type high stability structure.

High rigidity stroke axis: All axes are equipped with wide hard rails, optimizing the dynamic rigidity of the main sliding module, further enhancing the capability for strong cutting.

Equipped with high rigidity ball screws and couplings with three rows of bearings, ensuring high precision and rigidity of each axis. The ball screws are equipped with nut cooling to ensure stability during movement.

More news