19

2022

-

12

Flexible automated processing line for internal piston shafts

The inner piston shaft is an important component within the transmission, and its manufacturing process is complex. A key challenge in processing is how to better ensure the dimensional and geometric tolerances of the outer circle of the part with respect to reference points A and B.

The inner piston shaft is an important component in the gearbox, with a complex manufacturing process. The difficulty in processing lies in how to better ensure the geometric tolerance of the outer circle of the part with respect to reference A and B.

The flexible automated processing line for the inner piston shaft designed and built by Beijing Smart Technology Co., Ltd. uses Dean high-speed gauge CNC lathe Lynx225 paired with two sets of truss systems to complete the turning of the part in three processes; it employs Dean high-speed drilling and tapping center T4005, paired with two sets of multi-joint robotic automation systems to complete the processing of the spatial hole system of the part, as well as all processing from blank to finished product.

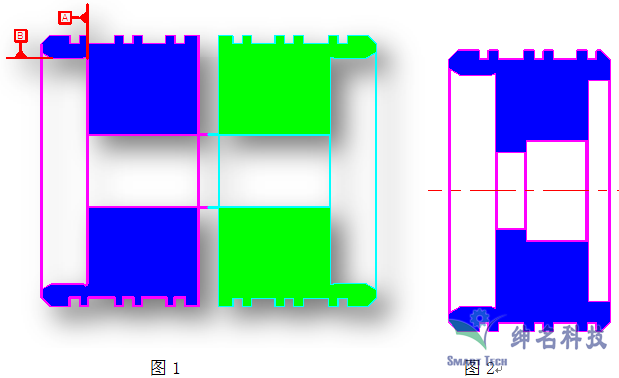

To address the processing difficulties, we adopted a "one split into two" processing technology, that is, one blank produces two products (Figure 2). A single blank is processed at both ends (Figure 1), and the inner hole reference on one side and the corresponding outer circle can be completed in one clamping, which not only ensures the processing accuracy of the part but also improves the clamping rigidity of the part. Then, a dedicated breaking mechanism is used to achieve the "one split into two" to complete the processing of this step.

The design of this production line is reasonable and operates stably, not only improving the chaotic use of workshop equipment and the complex processing methods but also saving labor costs and reducing equipment investment costs. It integrates the use of trusses and multi-joint robots, achieving digital management and improving production efficiency.

More news