30

2022

-

05

Industry Application | Hydraulic Valve Body Automation Line

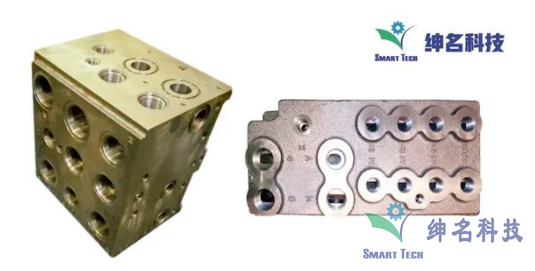

The valve body is used in hydraulic systems for fluid direction control or flow control, and there are many types with a high demand for production. Beijing Smart Technology Co., Ltd. provides an automated line for hydraulic valve bodies mainly used in the construction machinery industry, such as hydraulic components for cranes, excavators, and other hydraulic systems. According to the operation method, they can be classified into electric, hydraulic, and electro-hydraulic types. Additionally, based on the structure of the valve, there are various forms such as sliding valves and rotary valves, making their applications very extensive.

The valve body is used in hydraulic systems for fluid direction control or flow control. There are many types and a high demand for production. Beijing Smart Technology Co., Ltd. provides an automated line for hydraulic valve bodies mainly used in the construction machinery industry, such as hydraulic components for cranes, excavators, etc. They are classified by operation method into electric, hydraulic, and electro-hydraulic types, and by valve structure into various forms such as slide valves and rotary valves, making their application very widespread.

Processing difficulties:

The processing precision requirements for the valve body are high. Due to the numerous processing surfaces, efforts are made to concentrate the processes during the optimization of traditional techniques to reduce product clamping time and frequency, thereby improving production efficiency and ensuring the flatness of the valve body and the precision of important dimensions such as the valve core hole.

Production line characteristics:

This production line uses Doosan's high-speed and efficient vertical machining center to complete the process in two clamping stages, combined with modern robots for loading and unloading the valve bodies, L-shaped or T-shaped placement. It occupies a small area and has an efficient layout. The entire line consists of robots, machine tools, material storage, flipping/caching devices, etc.

Results:

The automated production line for hydraulic valves provided by Beijing Smart Technology Co., Ltd. has helped customers significantly improve production efficiency and the stability of product dimensions. This production line addresses issues such as poor consistency of blanks and unstable casting allowances by configuring automatic measurement systems, tool wear detection systems, and other methods, effectively reducing the failure rate during automatic operation and improving production efficiency. This automated production line has reduced labor costs while achieving low or no human involvement in production and management.

More news